Designed and Built in the USA

From raw steel to finished product. When you choose Hunter, you’re investing in more than 1,000 American workers.

Locations

St. Louis, MO

Headquarters & R&D

Products

- Alignment Sensors

- Balancer Collets

- Inspection Sensors

- Research & Testing

Durant, MS

Fabrication & Assembly

Products

- Alignment Racks

- Swing Jacks

- Drive Over Tread Depth

- On-Car Brake Lathes

- Bench Lathes

Raymond, MS

Electronics Manufacturing

Products

- Circuit Boards

- Cables & Wire Harnesses

- Electronic Subassemblies

Raymond, MS

Fabrication & Assembly

Products

- Alignment Systems

- Wheel Balancers

- Revolution™ Tire Changer

Processes

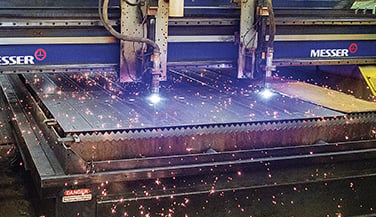

Laser & Plasma Cutting

Hunter uses state of the art fiber optic lasers and plasma cutters to turn sheet and plate steel into precision cut parts

Fabrication & Welding

Hunter’s team of certified welders along with a fleet of welding robots ensure industry-leading precision and quality go into each part.

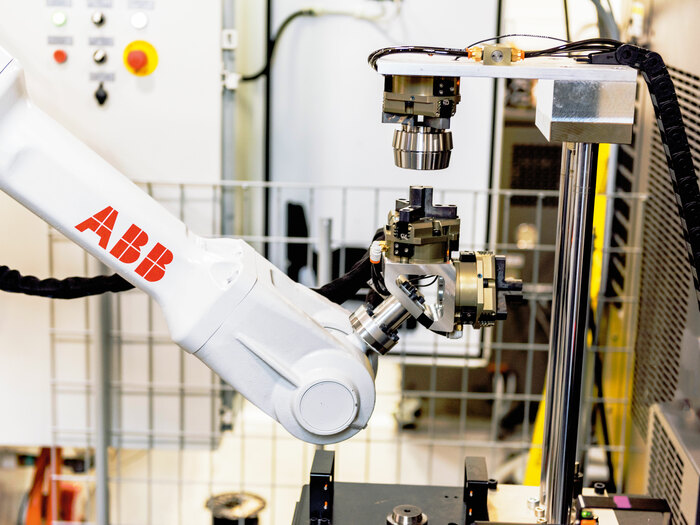

CNC Machining

Skilled machine operators use CNC milling machines and cutting-edge robotic systems to manufacture high-precision components.

Powder Coating

Hunter products undergo a cleaning and phosphate process followed by high performance powder-coating for world-class appearance, durability and corrosion resistance.

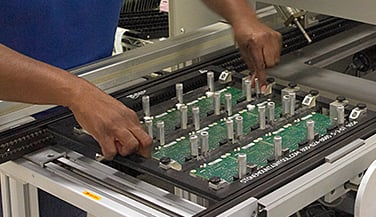

Circuit Boards

To ensure quality and reliability Hunter designs and builds circuit boards in-house with state-of-the-art equipment. Hunter produces over one million boards and cable assemblies every year.

Assembly & Testing

Hunter assemblers and inspectors undergo months of training and testing to become certified. Each part undergoes multiple levels of inspection to ensure it’s right before it leaves our plant.